Category

Mobile Phone Plastic Back Cover, Tempered Glass Making Machine

Mobile Phone Plastic Back cover,Tempered Glass Making Machine Application industries of Backside double-head CNC precisi

Basic Info

| Model NO. | DA-750DB |

| Cover | Half Cover |

| Transport Package | Wood |

| Specification | 1850KG |

| Origin | China |

| HS Code | 8459619000 |

| Production Capacity | About 1500 Sets/Year |

Product Description

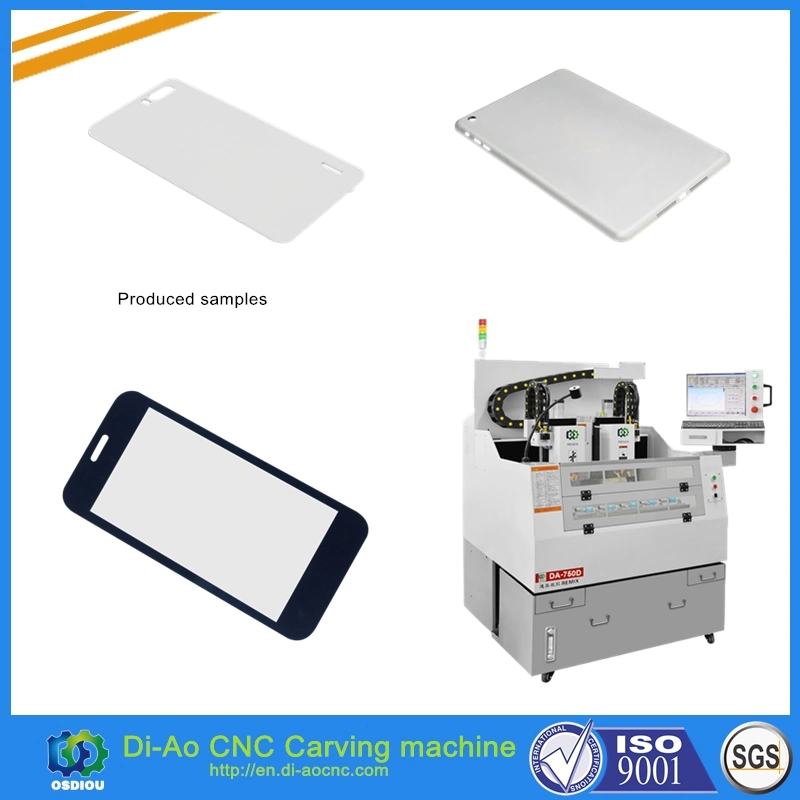

Mobile Phone Plastic Back cover,Tempered Glass Making Machine

Application industries of Backside double-head CNC precision carving machine

1.Opening holes and shape processing of glass lenses.2.Cutting and chamfering of PC, acrylic and PET window lenses.3.Batch processing of mobile phone panel and mobile phone buttons.4.Batch processing of mobile test fixture.5.Processing of precision electrode, sample, jewelry, glasses, clocks, hardware machinery, and aluminum alloy parts.

Features of backside type double-head precision carving machine:

1.The precision carving machine adopts Jinan blue granite, which has been precipitated for over 100 million years, with high precision of non-deformation and no vibration during processing.2.THKC3 high precision wire rod is imported from Japanese.3.THKP paired guide rail also is imported from Japanese.4.The original THK matched bearing has high precision and long service life.5.Automatic oil supply system, regular oil supply, longer service life.6.High precision, high sensitivity, Japanese METROL cutter setting instrument.7.The spindle is equipped with industrial water chiller, with constant working temperature and long service life of the spindle.8.Flexible cables are resistance to bend1 million times.

Core parts of CNC Engraving machine is from below suppliers:

Di Ao CNC Cutting machine factory:

CNC engraving machine specification:

| CNC Machine Specifications | |||

| 1 | ITEM/MODEL | DA-750SQ(Single head & full cover ) | DA-750DB(Double-head &Half cover) |

| 2 | Processing Materials | Acrylic/PC/PET | Phone Cover Glass |

| 3 | WORKING TABLE | ||

| 4 | Table size | 700×500mm | |

| 5 | Max load capacity | 50kg | |

| 6 | MOVEMENT & RANGE | ||

| 7 | X*Y*Z | 500×500×100mm | 350×500×100mm |

| 8 | Spindle clip to worktable height | 100/High beam150mm | |

| 9 | ACCURACY | ||

| 10 | Positioning accuracy | 0.008/300mm | |

| 11 | Repeatability accuracy | 0.005mm | |

| 12 | SPINDLE | ||

| 13 | Spindle power | 1.8Kw | |

| 14 | Spindle speed | 60000 rpm | |

| 15 | Spindle number | 1 pc | 2 pcs |

| 16 | Spindle spacing | - | 330mm |

| 17 | Spindle cooling | water cooling | |

| 18 | FEEDING SPEED | ||

| 19 | Rapid traverse | 15m/min | |

| 20 | Cutting feed rate | 9m/min | |

| 21 | REQUIRED POWER | ||

| 22 | Air pressure | 0.4~0.6 Mpa | |

| 23 | Power supply | 220 v | |

| 24 | Max Power | 5.8Kw | 8Kw |

| 25 | Machine Size | ||

| 26 | Machine weight | 1700kg | 1600/1850kg |

| 27 | Machine size | 1520*1460*1750mm | |

| 28 | Workpiece cooling | ||

| 29 | Workpiece cooling | Coolant/mist spray | |

| 30 | |||

| 31 | Optional components | ||

| 32 | Tool setting instrument | Optional | |

| 33 | |||

| 34 | CNC System Specifications | ||

| 35 | System Brand | Weihong Ncstudio | |

| 36 | Motion Axis | 3 Axes | 4 Axes |