Category

Automatic Glass Bottle Purero Water Tea Beverage Liquid Filler Packing Washing Filling Sealing Oil Packaging Beverage Machine Bottling System Machine

Product description: General description:This machine adopt to bottle block neck transit technology, realize full auto s

Basic Info

| Model NO. | TG-24-24-8 |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Rotor |

| Filling Principle | Atmospheric Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Appliance | Bottle Water, Juice, Beer, Carbonated Beverage |

| Capacity | 1000bph, 3000bph, 6000bph, 9000bph, 23000bph |

| Suit Bottle Type | 250ml, 500ml, 750ml, 1000ml, 1500ml, 2000ml |

| Filling Type | Reflux Type |

| Delivery Time | 40-50day |

| Bottle Type | Plastic Bottle or Glass Bottle |

| Advantage | Complete From Bottle Making to Finally Pack |

| Contain Machine | RO Water Treatment, Filling, Labeling, Packing |

| Afer Sale Service | Engineer Go Local Install, Train Buyer Use |

| Transport Package | Most Machines Wooden Case Package |

| Specification | 8-8-3 16-12-6 24-24-8 32-32-10 40-40-12 |

| Trademark | tango |

| Origin | Zhangjiagang, China |

| HS Code | 8422301090 |

| Production Capacity | 2000-20000bph |

Product Description

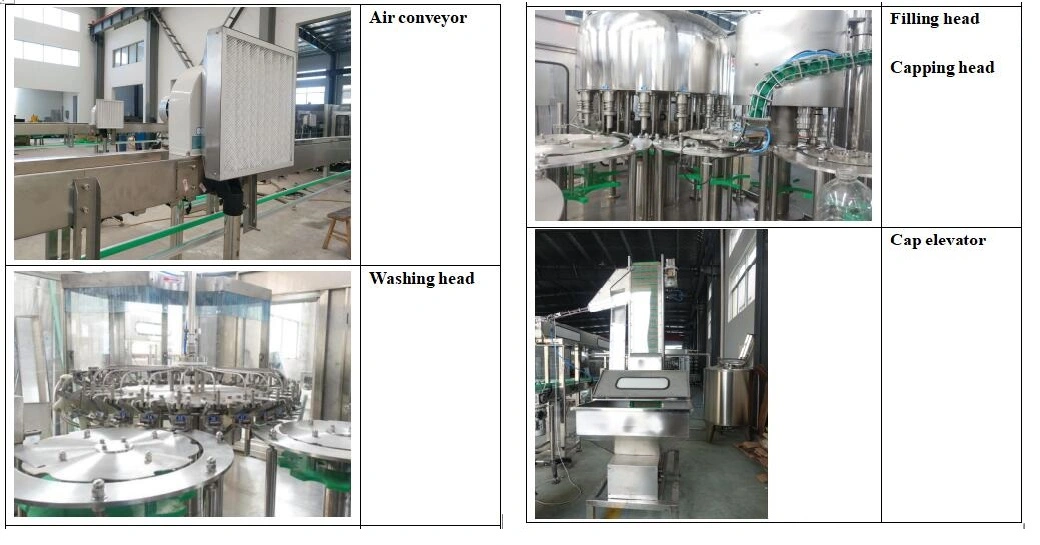

Product description:General description:This machine adopt to bottle block neck transit technology, realize full auto sterilizer, bottle washing, juice filling or pulp filling,capping ect technology, high auto degree; pulp filling machine adopt to volume filling technology. Match complete temperature control system and reflux sytem, set complete auto cleaning system and control program, match liquid contact spare parts full use super stainless steel material and food degree rubber.Pulp filling machine Pulp hot filling facility adopt to block neck transit technology, realize auto sterilizer, bottle washing, pulp filling, capping ect procedure, high auto degree; pulp filling realize single gravity volume filling technology; match complete temperature controlling system and reflux system, set complete auto cleaning system and control procedure, all part that contact liquid all use stainless steel material and food degree rubber. Filling inner fracture:

| Model(CGFB) | 16-12-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-15 |

| Washing head | 16 | 18 | 24 | 32 | 40 | 50 |

| Filling head | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping head | 6 | 6 | 8 | 10 | 12 | 15 |

| Capacity(500ml) | 4000BPH | 6000BPH | 1000BPH | 1200BPH | 16000BPH | 24000BPH |

| Power | 3.8kw | 4.3kw | 6.5kw | 8.7kw | 9.5kw | 12kw |

| Overall size L*W*H | 3050*2000*2400mm | 3170*2070*2400mm | 4070*2350*2400mm | 5100*2600*2400mm | 6250*3050*2400mm | 7500*3900*2400mm |

Auxiliary machinesFlow chart:Client list bottle samples:Factory photo:Some key affair that client interest as follow:

Installation:After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.We will send engineer, client pay ticket turn and back, and engineer each day usd50 cost. |

| How long time for installation? After machine arrive local, if client ready raw material, connect water pipeline and electricity, after prepared visa, we will send technician as client project situation to client factory, it will take about half month install, half month train custom engineer how to use and maintain machine. |

Training machine use and maintainOur company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures. |

Machine quality GuaranteeWe promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic. |

After salesAfter checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician. After salesAfter checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician. |

Can we see machines operation at our country ? A1: We have installed many project at many countries. If u need see, we need talk customer that who bought from us, if they allow, then we will tell u contact info , u can visit them.We advise client come visit our company, u can know our company and see our machines operation at workshop.We will arrange car go pick up from nearby train station or airport. Welcome local joint us. |

We will supply technology:We will make solution as client bottle size, workshop space,budget...We can help client design bottle and label. Make workshop layout as space size. |

Spare parts: will send one year spare parts with machines together. |

| Are u trading company or manufacturer ?We are manufacturer, we have own export company. |

Delivery time: 30-60day |

What info need to supply before we make offer solution.

|

| Chemical Reactor | Laboratory Reactor | Flow Meter Filling Machine | Lubricant Oil Reactor |

| Piston Filling Machine | Semi-Auto Filling Pressing Machine | Stainless Steel Reaction Vessel | Weight Filling Machine |

| Dry Mortar Concrete Mixer | Liguid Mixing Dispenser | Resin Reactor Vessl | Double Conical Sold Mixer |