Category

Glass Tempering Furnace Glass Tempering Machine Price Tempered Glass Making Machine Glass Toughening Machine Glass Processing Machine Glass Machine

Overview of ZK2436 (5-19mm) horizontal roller type tempered glass unit AT-TAQ2436 (5-19mm) series forced convection temp

Basic Info

| Model NO. | ZK2436 (5-19mm) |

| After-sales Service | Lifetime Warranty |

| Glass Thickness | 5 -19mm |

| Maximum Specification | 2440*3660 |

| Minimum Specification | 100*300 |

| Comprehensive Yield | Not Less Than 98% |

| Glass Quality | Better Than The National Standard |

| Power Consumption | Less Than 3.5 °/M2 - 5mm |

| Production Quantity | 16-18 Heats/Hours - 5mm 13-15 Heats/Hours - 6mm 9- |

| Glass Raw Material Requirements | The Bubbles and Inclusions Can Be Removed, Which C |

| Heating Power | 535kw |

| Fan Power | 185kw |

| Hot Air Fan Power | 3×4kw |

| Other | 20kw |

| Transformer | 630 kVA |

| Colour | White |

| Frequency | 50Hz,60Hz,Customised |

| Transport Package | Wooden Box, Steel Frame |

| Trademark | Zhengke |

| Origin | Shandong, China |

| HS Code | 8475291900 |

| Production Capacity | 1000 Sets/Year |

Product Description

Overview of ZK2436 (5-19mm) horizontal roller type tempered glass unit

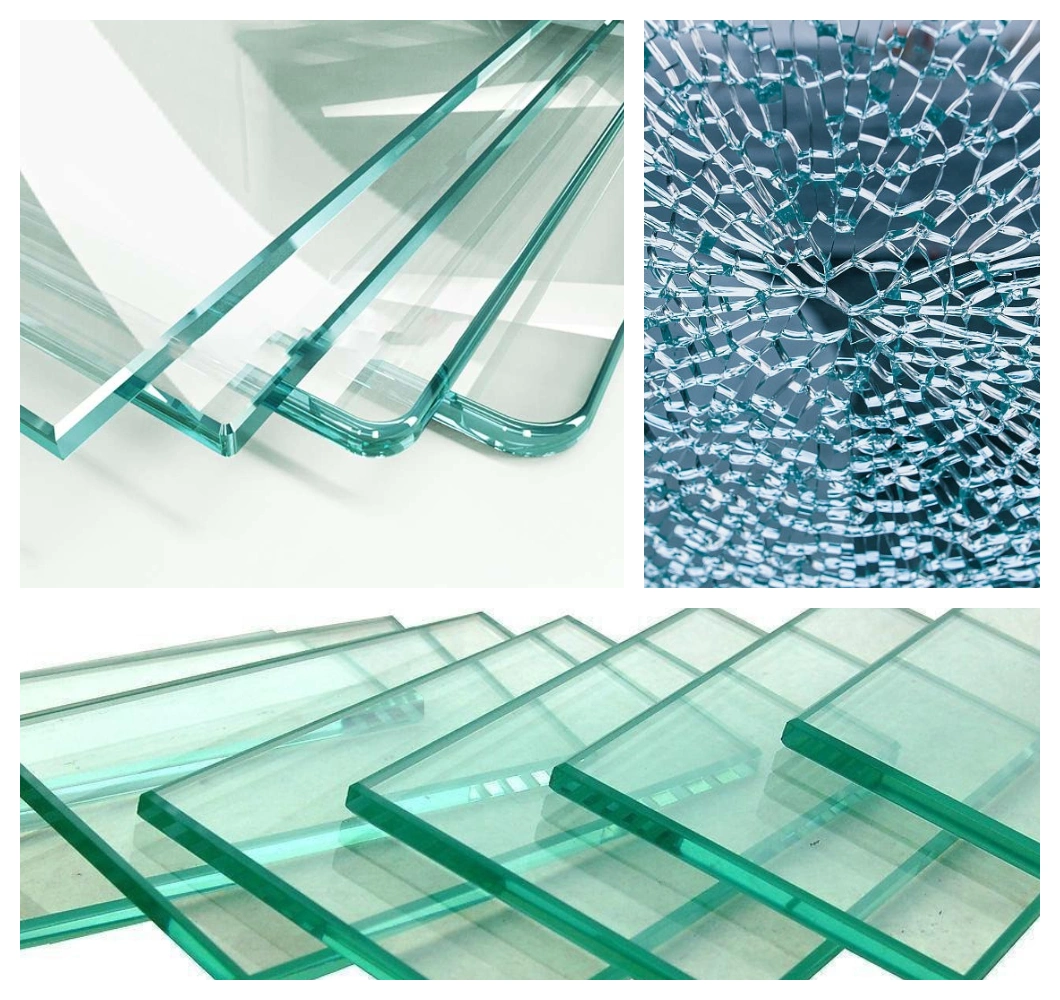

AT-TAQ2436 (5-19mm) series forced convection tempering electric furnace is the new generation of tempered glass produced by China Furnace. Compared with domestic and foreign products, the glass tempering machine has the advantages of reasonable technology, strong system control software function, reliability, excellent thermal insulation performance, low energy consumption, computer dynamic control, and production efficiency, especially suitable for the deep processing of Low-E glass, coated glass and other glass products.Features:The specially designed convection cooler has more stable and reliable temperature performance and excellent convection effect.The most advanced convection circulation structure is designed to ensure faster and more uniform heating of glass.The design and layout of heating elements are unique and reasonable. With the most advanced remote temperature control module, the temperature control is extremely accurate and the adjustment is simple, effectively ensuring the uniformity of temperature in the furnace.The running speed of the convection fan is controlled by the frequency converter, and given by the computer, so that the upper and lower tables of the glass are heated, which greatly improves the product quality.High quality thermal insulation materials are selected inside the furnace to effectively control the production of various particles and the resulting impact on glass quality.High quality thermal insulation materials are selected inside the furnace to effectively control the production of various particles and the resulting impact on glass quality.The circulation formed by the convection fan is completely fed into the furnace, which will not cause heat loss due to convection, and the energy-saving effect is good.It can be used to add various float glass, embossed glass, Low-E glass, etc. The E minimum value of Low-E glass is up to 0.05The added glass has good optical quality and is free of heating defects such as pits, roller marks and roller tracks. Better strength and particle size of glass.

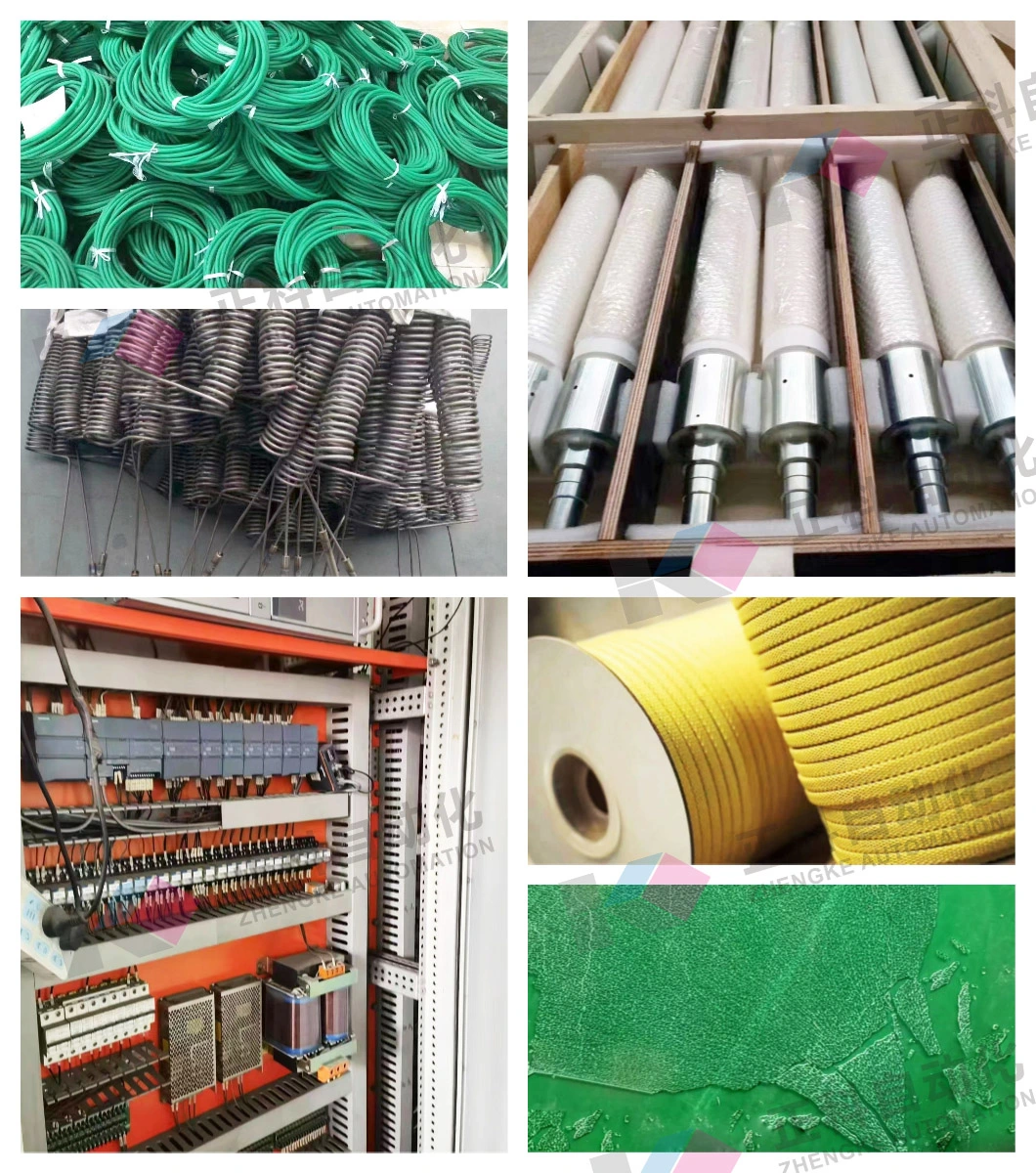

Detail Photos:

Equipment structure and operation principle:The equipment includes upper and lower sets, heating section, flat steel cooling section, lower sets, cooling system and control system. The flat steel glass raw material enters the heating furnace from the upper one, and after heating in the heating furnace, it enters the cooling section of the flat steel grid for tempering and cooling, and the final product arrives at the next one for unloading.

Sample PhotosPacking Details

Company Profile

Shandong Zhengke Automation was founded in 2014, located in Jiyang Industrial Park, Jinan, Shandong Province. The company covers an area of 5000 square meters, the core team of 50 people. Have independent technology design, research and development team. Have modern office space. Is the domestic professional glass machinery high-tech enterprises.The company focuses on glass cutting machine.glass edging machine.glass washing machine.glass tempering machinery.insulating glass machine.glass tempering machine.laminated glass machine...etc. The company has more than 1500 terminal customers, with good reputation, won the recognition of the majority of customers.We have 2 independent technical patents, 12 Copyrights and 2 trademarks. The company developed a series of glass two-component glue machine advanced technology, sensitive reversing, continuous stability, high production efficiency, high degree of automation, easy to use; Widely used in two-component silicone structural adhesive, polysulfide adhesive, polyamine glue and other high accurate ratio, uniform mixing and fast operation occasions. Solve the phenomenon of high waste and low efficiency caused by manual work, is the ideal glass bonding production machine.The company adheres to the business philosophy of "Honest and trustworthy, and prosper enterprises with science and technology", based on talent, technology, service and reputation, not only to provide customers with high quality glass machine, but also to provide you with case debugging machine, technical consulting guides, staff operation training and other comprehensive after-sales service.

- We provide professional glass production solutions.

- Professional online service team, any mail or message will reply within 24 hours.

- We have a strong team provide wholehearted service to customer at any time.

- We insist on Customer is Supreme, Staff toward Happiness.

- Put the Quality as the first consideration;

- OEM & ODM, customized design/logo/brand and package are acceptable.

- Advanced production equipment, strict quality testing and control system to make sure superior quality.

- Competitive price: we are a professional glass machine manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us.

- Good quality: good quality can be guaranteed, it will help you keep the market share well.

- Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.