Category

Jumbo Size 3300X6000 Insulating Glass Gas Filling Igu Machine

Application Vertical automatic insulating glass flat press production line is mainly used for Insulating Glass Units (al

Basic Info

| Model NO. | LBZ3360 |

| Condition | New |

| After-sales Service | One Year Guarantee, All Life Long After Service |

| Jumbo Size | 3300 |

| Half Freight | Bendable Structure for Gp |

| Gas Filling | Online Gas Filling |

| Gas Filling Percentage | 90% |

| Function | Gas Filling Insulating Glass Line |

| Transport Package | Seaworty Package |

| Trademark | DETEK |

| Origin | China |

| HS Code | 8464901900 |

| Production Capacity | 300sets/Year |

Product Description

Application

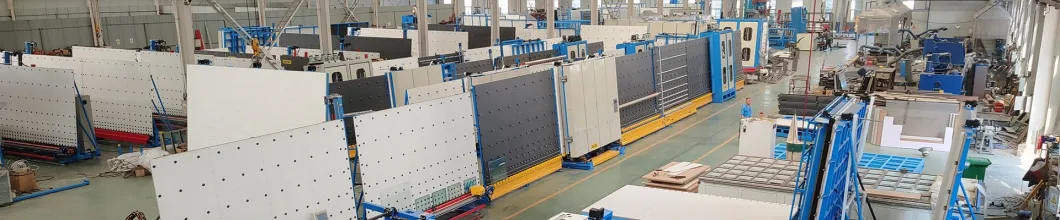

Vertical automatic insulating glass flat press production line is mainly used for Insulating Glass Units (also known as double glazing glass, or double glaze) production. Our LBZ3360 model applies for glass processing company, and windows & doors processor/fabricator. Fully automatic glass sheet transportation through the whole line, automated Low-E coating detection, auto glass washing and drying, fully automatic IGU assembly and pressing with optional gas filling on line, and finally automatic secondary sealant sealing assure high quality insulating glass unit, which guarantees the long life top performance.

Feature

- PLC control system with touching screen interface

- Automatic distinguish the coating side of Low-E glass.

- Perfect washing performance for on/off line Low-E glass.

- Unique air knife with silencer device.

- Automatic aluminum frame mounting system.

- Auto glass positioning system

- Inside and outside assembly and press function.

- On-line gas filing, and auto glass size checking system for gas filling time.(Option)

- Double IGu, triple IGu, shaped IGu and stepped IGu(Option).

- Bendable mechanical structure for general container loading, save freight.

Glass washing section

Feature

- Automatic distinguish the coating side of Low-E glass, front 3 soft low-E brushes.

- Unique air knife and silencer for washing machine.

- The washing zone and water tank are made of stainless steel and corrosion-proof material. Water heating system available.

- The conveyor rollers are made of rubber, resistant to acid and alkali.

- Automatic adjustment of glass thickness from 3mm to 12mm.

- Drive speed adjusted by inverter stepless, the glass runs stably at proper speed.

- Three pairs of brushes, with high-pressure water spray nozzle.

- In the drying zone, there is a pair of alloyed and corrosion-proof air knife, installed angularly, generate strong air flow to dry both sides of glass.

- Three independent water circulating system: the first washing water system, the second washing water system and rinse water system.

- To ensure the washing quality, the water conductivity should not exceed 40µs/cm.

- 15KW blower with heating system.

Pressing station section

Feature

1. Ultra-long insulating glass can be processed in this pressing robot.

2. Pressing plate with precisely adjustable screw for flatness adjustment.

3. Maintenance open up to 650mm for easy maintenance.

4. Servo motor drives synchronous belt for assembly and pressing.

5. Stepped IGu and on-line gas filling available.

Parameter

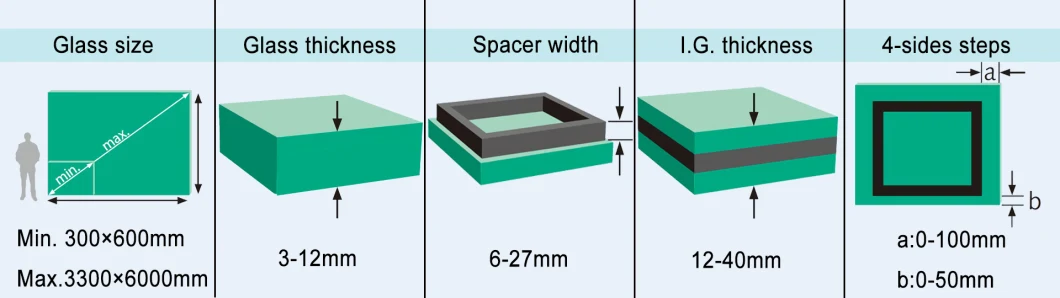

| Max. IG size | 3000×6000mm |

| Min. IG size | 300×600mm |

| Single glass thickness | 3-12mm |

| Insulating glass thickness | 40mm |

| Glass washing speed | 2-10m/min |

| Washing brushes | 3 pairs |

| Glass conveyor speed | 45m/min |

| Conveyor wheel height | 520mm |

| Air supply | 0.8m3/min(1Mpa) ≥0.8Mpa |

| Water supply | 0.5t/h conductivity≤40μs/cm |

| Power | 3P 380V 50HZ 55kw |

| Dimension | 42500×3200×4200mm |

| Weight | 10000Kg |

Brand parts list

| Name | Brand | Country |

| PLC | Siemens | Germany |

| Servo driver | Siemens | Germany |

| Servo motor | Kinco | China |

| Touching screen | Kinco | China |

| Inveter | Omron | Japan |

| Breaker | S chneider | French |

| Contactor | S chneider | French |

| Relay | S chneider | French |

| Indicator | S chneider | French |

| Knob | S chneider | French |

| Sensor | Omron | Japan |

| Proximity switch | IFM | Germany |

| Solenoid | Airtag | TAIWAN |

| Air cylinder | Airtag | TAIWAN |

| Power supply | MW | TAIWAN |

| Solenoid | Airtag | TAIWAN |

| Air cylinder | Airtag | TAIWAN |

| Power supply | MW | TAIWAN |

| Guider | TBI | TAIWAN |

Mostly asked questions below:

1. What is your soonest lead time?

A: 60 days for whole production line, 30 days for single machine. Special requirement pls check with sales.

2. How do you arrange the shipment?

A: all machines fit GP for sea freight saving. Seaworthy package, workshop container loading, safe arriving.

3. Guarantee ?

A: One-year guarantee (wearing parts are out of this range). Life long service. DETEK will send engineers for service upon request onsite.

4. How we can install the machines?

A: Installation included; however, customers need to pay our engineer's round way air tickets, local transportation and accommodation (hotel and food).

The installation should be finished within 15 days, and will be charged 60USD/engineer/day.

5. How about the after service?

A: Spare parts within 72 hours.

Experienced technical sales sort out most of your questions.

Tens of service engineers ready for on-site service and instruction.

Previous: Automatic Liquid Bottling Equipment Bottle Cap Machine Small Bottle Filler Glass Vials Filling and Sealing Pharmaceutical Medicine Bottle Liquid Filling Machine

Next: 6000-12000bph Automatic Spring Drinking Pure Water Juice Carbonated Drinks/Juice Liquid/Glass/Can Bottle Washing Filling Capping/Bottling Making Packing Machine

Send inquiry

Send