Category

TBR Full Convection Flat Glass Tempeirng Processing Machine for Float Glass Clear Glass Low-E Glass

GUANGDONG SHUNDE TIMBERY TECHNOLOGY CO.,LTD.Full convection system tempering furnace introduction:1: Production capacity

Basic Info

| Model NO. | TG2650-A |

| Condition | New |

| Heating Method | Top Convection Heating |

| Heating Balance | Yes |

| Convection | Full Convection |

| Blower | 2 Sets |

| PLC | Omron |

| Screen | Philips |

| Transport Package | Container |

| Specification | CE |

| Trademark | Timbery |

| Origin | Guangdong |

| HS Code | 8419899090 |

| Production Capacity | 8set/ Month |

Product Description

GUANGDONG SHUNDE TIMBERY TECHNOLOGY CO.,LTD.Full convection system tempering furnace introduction:1: Production capacity information| Glass thickness | 4mm | 5mm | 6mm | 8mm | 10mm | 12mm |

| Batch/H | 18-19 | 15-16 | 13 | 10 | 8 | 5 |

2: Popular models information:

| Model | MAX | MIN | GLASS THICKNESS | KVA |

| TG2436-A | 2440X3660 | 300X150 | 4-19MM | ≥500 |

| TG2442-A | 2440X4200 | 300X150 | 4-19MM | ≥550 |

| TG2450-A | 2440X5000 | 300X150 | 4-19MM | ≥630 |

| TG2460-A | 2440X6000 | 300X150 | 4-19MM | ≥800 |

| TG2650-A | 2600X5000 | 330X150 | 4-19MM | ≥800 |

| TG2850-A | 2800X5000 | 330X150 | 4-19MM | ≥800 |

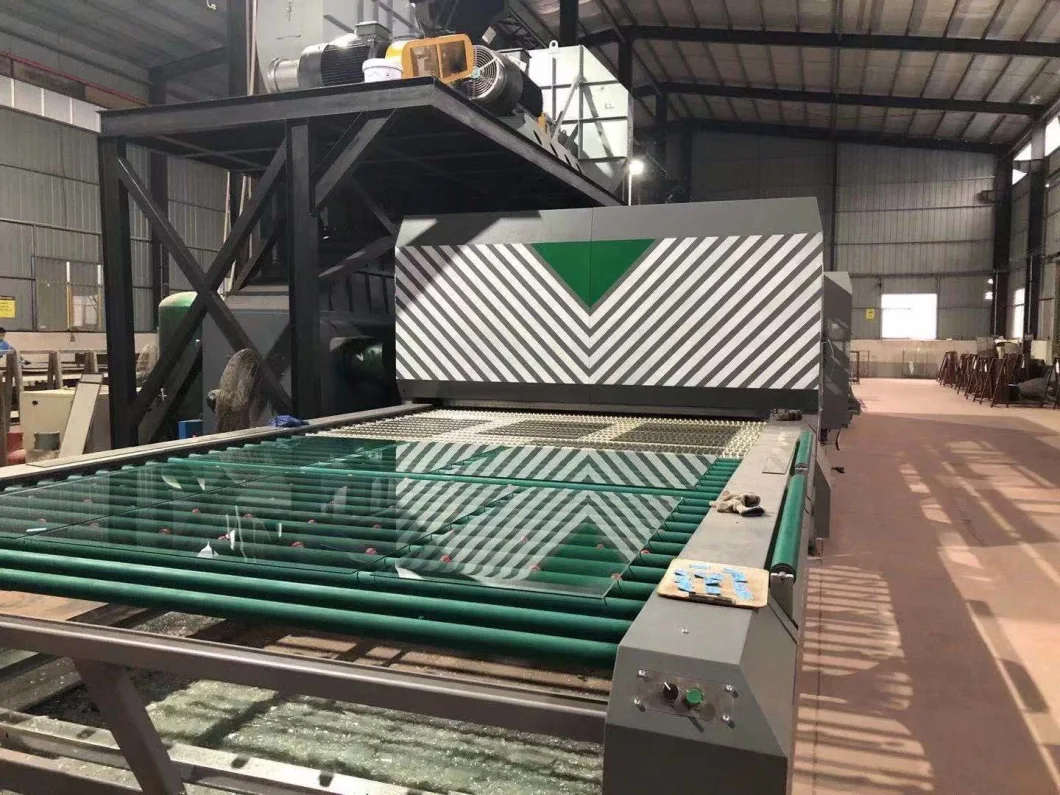

Glass tempering outlook:

Heating fuse configuartion

Cooling section

Unloading table

Glass finishing and flatess

| Technology Features |

| 1. Radiant panel installed in heating chamber, which can avoid broken glass drop and damage heating element and ensure the heat inside chamber is absorbed by glass evenly. It is also convenience for the heating parts maintenance. |

| 2. The heating chamber transmission adopts double round belt, orthogonal setting, which can ensure the stable running. High quality of aluminum silicate insulation scientifically sorting and precision cutting technology, it can be improved the heat efficiency and keep the low temperature outside of the furnace. |

| 3.The alloy sections and steel sheet is card slot design & cold riveted double protection design, which can avoid deformation of heat welding and high pressure long time condition. Air platoons can be adjusted in up-down, left-right, front-back these 6 position for multi-angle adjustment , it can make glass cooling effect is the best. |

| 4.Exclusive new radial arch design & adjustable plate inside design can aggregate the high pressure better. So high pressure air can distribute uniformity that ensures glass flatness will be better. |

| 5.Blower will automatically adjust to Zero Frequency in 60s before glass going out. This design will save more electricity consumption than 20Hz frequency. |

| 6.Pass section is design for 4mm glass, use 2 blower for cooling glass. When 4mm glass come out from heating chamber, big blower will open to quenching glass in pass section, after few second, big blower switch off and small blower on, glass transfer to cooling section for cooling. Advantage of pass section is 4mm glass can be full loading area, so production will be 50% higher than only use one bigger blower but half loading area. What is more, this design can be lower installation power and 60% energy saving for quenching. |

| 7.Fan convection use heat resistant motors to uniform heating in Chamber. Heating can keep inside, so it will be energy saving and shorten heating time. It is designed for efficient and research Low-E glass. it is now the world recognized as the most stable, safe, high efficiency, energy saving way of convection. |

Previous: Double Glazing Machine Double Glass Machine Insulating Glass Machinery Insulating Glass Machine Insulating Glass Production Line Glass Processing Machine

Next: Automatic Glass Straight Line Edging Polishing Grinding Beveling Mitering Round Pencil Processing Edger Line Machine Machinery

Send inquiry

Send